KEY PROPERTIES

TERRALAND TO semi-mounted chisel plough for deep loosening, including the option of replacing tines and rollers to switch the machine to a professional subsoiler.

Intense soil cultivation up to a depth of 21,7 inches.

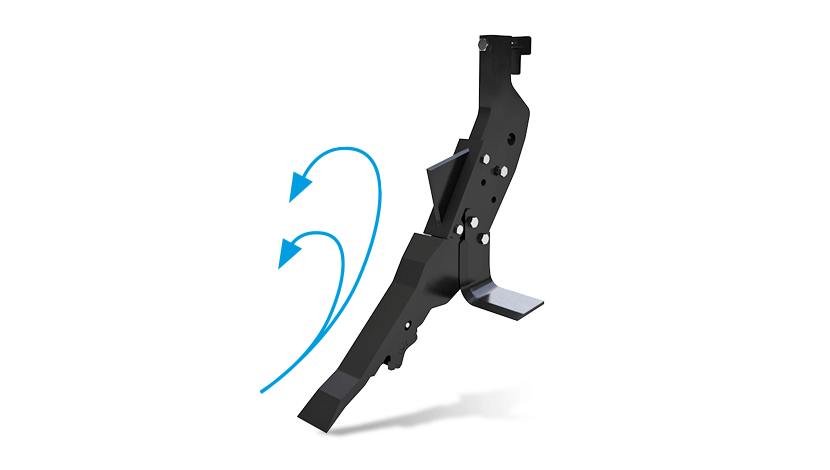

The semi-mounted chisel plough is made in working widths from 13 to 21 feet. The extremely robust frame made of brackets with a diameter of 5.9 × 5.9 inches in combination with the hydraulic tine protection enables intense deep soil cultivation up to a depth of 22 inches. The hydraulic NON-STOP protection provides a protection force for each tine in the range of 2 205- 3 307 lb.

TERRALAND TO both as a chisel plough and professional subsoiler.

Deep loosening

The TERRALAND TO chisel plough in combination with Active-Mix tines and spiked rollers is suitable for deep loosening. The special shape of the tines provides easy soil penetration, and excellent loosening and mixing effect. In one pass, the soil profile is loosened in depth and the soil surface is intensely mixed and levelled.

Subsoil tillage

The TERRALAND TO frame can be equipped with special Zero-Mix tines with a negative angle for subsoil tillage without active mixing of soil. This operation is suitable for removing hardened soil layers, aerating the soil profile, and creating a proper soil environment.

Two operations in one pass save time and money.

The TERRALAND TO chisel plough consists of two rows of tines, followed by tandem spiked rollers. Active tines provide deep soil loosening, tandem spiked rollers overlap and offer an excellent crumbling effect. The advantage of the rollers is that they can be adjusted according to the required work, for example, in rocky soils.

Soil cultivation without rear rollers in adverse conditions.

The TERRALAND TO semi-mounted chisel plough has an integrated transport axle between two rows of tines. This structural design lets you work with the TERRALAND TO semi-mounted chisel plough in extremely adverse conditions because the rollers can be easily put out of operation. It prevents undesirable clogging of rollers, allowing you to continue working. Moreover, the axle reduces the turning radius at headland and allows for an easy approach to the next take.

Soil cultivation without rear rollers in adverse conditions.

The TERRALAND TO semi-mounted chisel plough has an integrated transport axle between two rows of tines. This structural design lets you work with the TERRALAND TO semi-mounted chisel plough in extremely adverse conditions because the rollers can be easily put out of operation. It prevents undesirable clogging of rollers, allowing you to continue working. Moreover, the axle reduces the turning radius at headland and allows for an easy approach to the next take.

Reduced numbers of passes and soil compaction.

The CTF (controlled traffic farming) system eliminates soil compaction and optimises the passes of the individual sets. When working, the individual sets travel across the field in the given grid of the working width (19.7 – 39.4 – 59.1 – 78.7 feet etc.), which prevents the formation of uneven compaction in the field as well as in the tracks that can be easily tilled.

TECHNICAL DATA

MACHINE DESCRIPTION

For interactive machine description go to https://www.bednar.com/ca/terraland-to/