KEY PROPERTIES

A disc cultivator for smaller farmers with the properties of larger professional models, suitable for basic soil cultivation and seedbed preparation.

Its true name. See for yourself.

Stubble breaking after harvest

Stubble breaking is one of the most important field operations. According to the proper agricultural procedures, it should be done as soon after harvest as possible. For this operation, SWIFTERDISC XN can be equipped with serrated or aggressive discs with a diameter of 20.5 × 0.2 inches, providing excellent cutting, mixing with soil and incorporation of crop residue. The rear packers compact soil and close the cultivated soil profile to ensure even emergence of weeds and unwanted cereal seeds.

Seedbed preparation

The optimal diameter in combination with the high working speed provide a high circumferential speed of the discs, which leads to excellent crumbling and mixing effect of the disc section.

Especially suitable for work in extremely dry conditions.

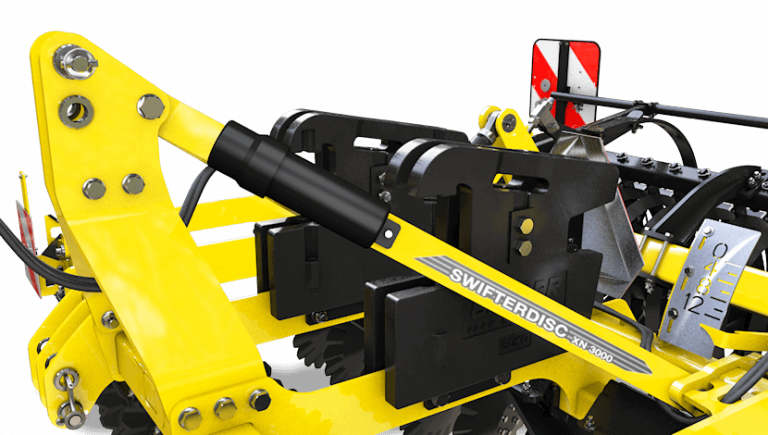

The mounted version of the SWIFTERDISC XN cultivator can be equipped with ballast weight from 220 to 441 kg. The ballast weight helps discs penetrate soil and improves their work, especially when working in dry conditions.

Prevents sections from getting clogged.

Despite their compact dimensions, the SWIFTERDISC XN cultivators have outstanding frame clearance. The distance between the front and rear disc rows is up to 31.5 inches. The frame clearance is about 23.6 inches and enables incorporation of larger quantities of crop residue or organic fertilizer.

Simple and easy catch crop establishment using a disc cultivator with a seeding unit.

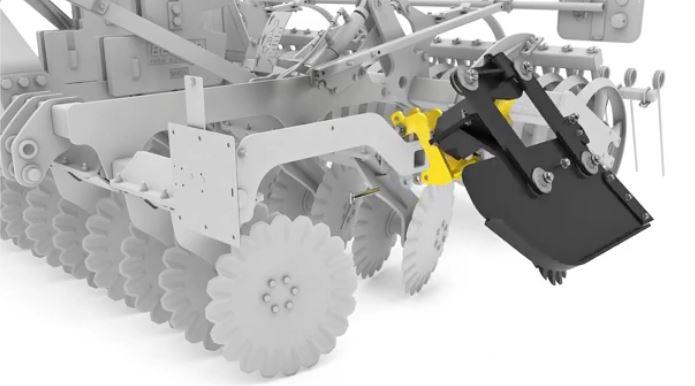

The SWIFTERDISC XN cultivator can be equipped with the BEDNAR ALFA DRILL seeding unit while in production, for seeding catch crop and small-seed plants during stubble breaking, all in one pass. The time and fuel savings are considerable. The seeding unit has a capacity of 11 bu.

Thanks to the folding side discs.

To ensure safe transport, the side discs are folded upwards. The discs are folded mechanically. The full working width is achieved by unfolding the side discs into the working position.

Even when travelling with a mounted machine.

The SWIFTERDISC XN cultivator is aggregated with the tractor’s three-point hitch. The compact and short frame of the disc cultivator ensures safe transport, because the centre of gravity is close to the rear axle of the tractor.

TECHNICAL DATA

MACHINE DESCRIPTION

For interactive machine description go to https://www.bednar.com/ca/swifterdisc-xn/