KEY PROPERTIES

SWIFTERDISC XE cultivators offer a series of technical solutions that make them suitable for both shallow stubble breaking and seedbed preparation

Its true name. See for yourself.

Stubble breaking after harvest

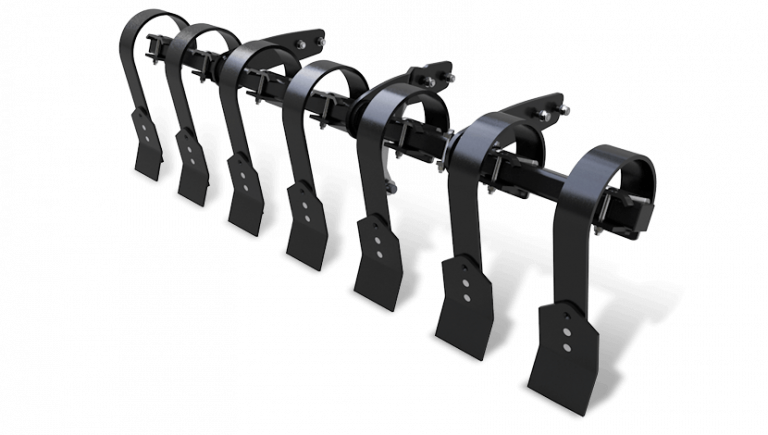

Stubble breaking is one of the most important field operations. According to the proper agricultural procedures, it should be done as soon after harvest as possible. For this operation the SWIFTERDISC XE can be equipped with serrated or aggressive discs with a diameter of 20.5 × 0.2 inches or 22 x 0.2 inches, providing excellent cutting, mixing with soil and incorporation of crop residue. The rear packers compact soil and close the cultivated soil profile to ensure even emergence of weeds and unwanted cereal seeds.

Seedbed preparation

The small disc diameter in combination with a high working speed provide a high circumferential speed of the discs, which leads to excellent crumbling and mixing effect of the disc section. If you are planning to use the disc cultivator for soil preparation more frequently, we recommend adding the front Crushbar leveller to the SWIFTERDISC XE for levelling and breaking the rough furrow.

Easy and fast disc cultivator working depth setting.

The required working depth is set precisely using hydraulics. The machine working depth can be easily set using tipping clips on the hydraulic cylinders of the disc cultivator.

Use the disc cultivator for soil preparation as well.

To increase the all-year-round utilization, the SWIFTERDISC XE wide cultivator can be equipped with the hydraulically controlled Crushbar leveller in the front. This combination provides perfect soil profile levelling, clod crumbling, and soil preparation.

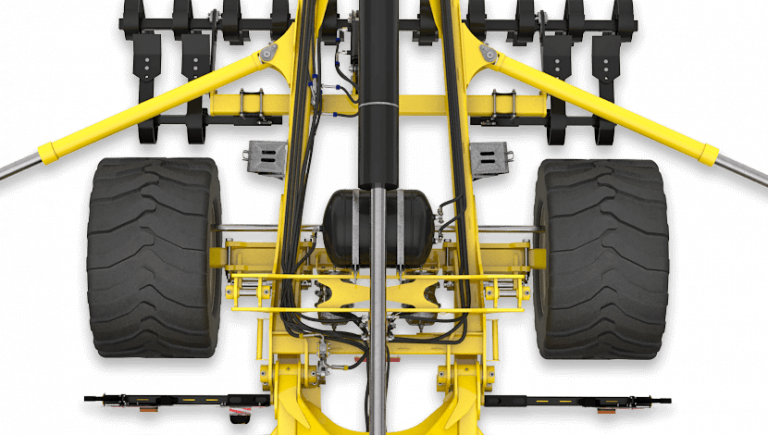

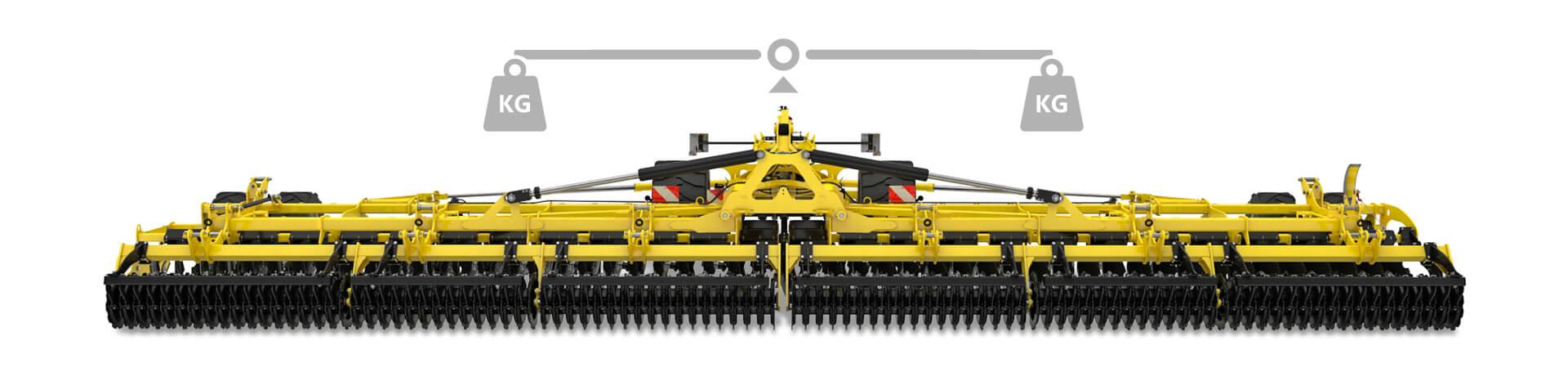

Contributes to ideal weight distribution.

The SWIFTERDISC XE wide disc cultivators have the transport axle shifted forward, in front of the first disc section row. This design contributes to ideal weight distribution and allows it to achieve higher working speeds. The telescopic connecting rods help stabilize frames where the disc sections are mounted.

Always the same down pressure on both frames of the disc section.

Maintaining the set working depth for even soil profile processing is the foundation of quality soil cultivation. The SWIFTERDISC XE cultivators provide the same pressure on discs along the entire machine width thanks to the axle being moved forward and the concept of two folding side frames. The structural design of the machine reduces the number of hydraulic cylinders where side frame pressure could be lost. This design also reduces the number of points of lubrication, the overall wear of the machine, and it simplifies manipulation with the machine, both in the field and on the road.

Always the same down pressure on both frames of the disc section.

Maintaining the set working depth for even soil profile processing is the foundation of quality soil cultivation. The SWIFTERDISC XE cultivators provide the same pressure on discs along the entire machine width thanks to the axle being moved forward and the concept of two folding side frames. The structural design of the machine reduces the number of hydraulic cylinders where side frame pressure could be lost. This design also reduces the number of points of lubrication, the overall wear of the machine, and it simplifies manipulation with the machine, both in the field and on the road.

Provides compact dimensions and safe transport.

Even with the working width of 40.7 feet, the SWIFTERDISC XE cultivator is very compact in transport mode, because it does not exceed the transport width of 10 feet and the height of the machine is just below 13.1 feet. Such parameters are achieved thanks to the forward side frame folding, towards the drawbar.

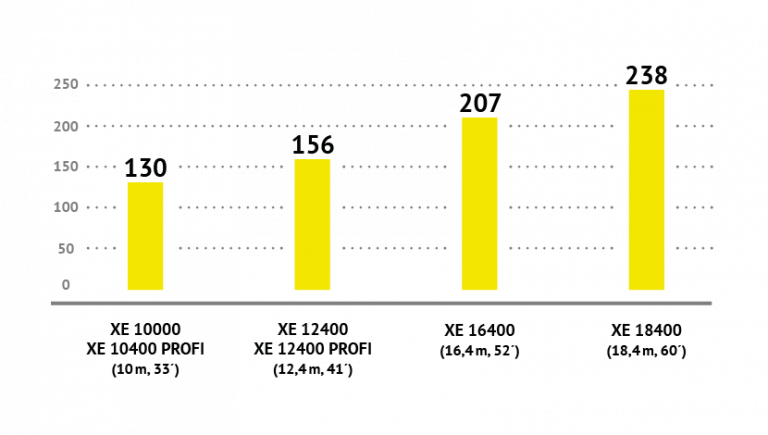

Do more for less with maximum daily output.

The wide-span SWIFTERDISC cultivators are designed for aggregation with the most powerful tractors on the market. These cultivators offer maximum daily output thanks to their sophisticated design and high working speed.

TECHNICAL DATA

MACHINE DESCRIPTION

For interactive machine description go to https://www.bednar.com/ca/swifterdisc-xe_classic/