KEY PROPERTIES

A professional cultivator with a standard design suitable for traditional soil cultivation, as well as minimization systems.

Creating a seedbed for proper and even crop emergence.

Combining several operations into one means fewer passes through the field and lower costs of soil preparation. The front levelling bar or leveller perfectly levels off any unevenness. The front crumbling roller crumbles the clods. The main working section undercuts, aerates and warms up the soil layer. The final clod crumbling is provided by various types of rollers in combination with other equipment behind the rollers.

Adjusting soil cultivation to the needs of the crop.

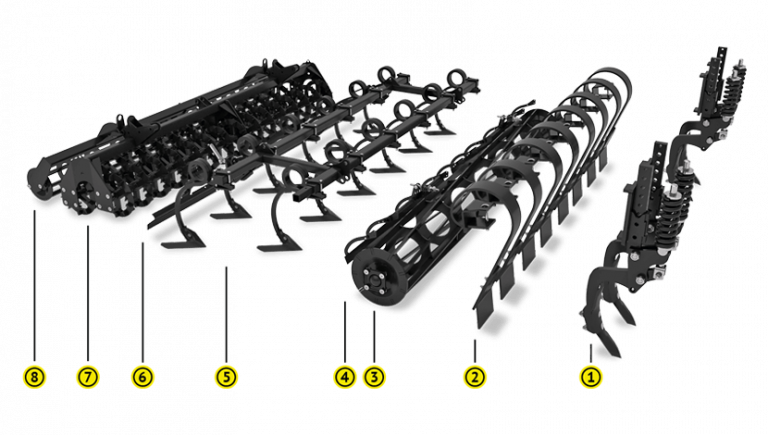

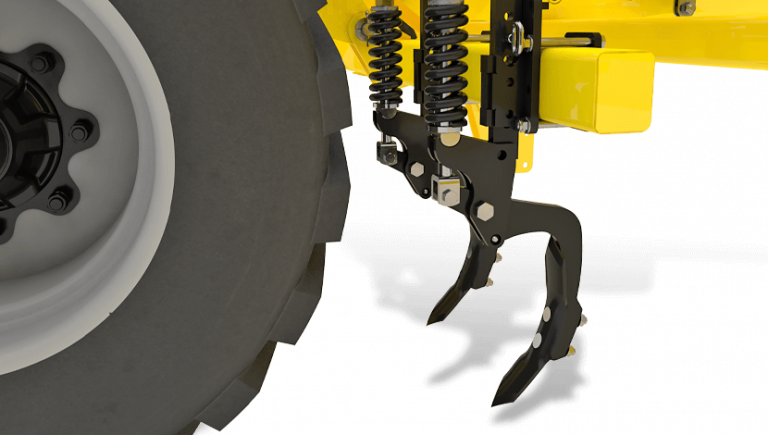

Sweep section

A sweep working section (summer and autumn soil cultivation – winter cereals, oilseed rape)

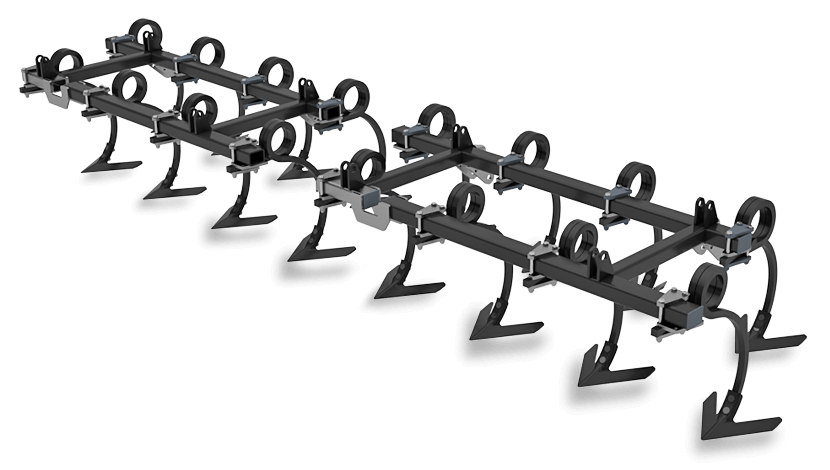

This working section can be used for summer and autumn preparation when soil needs to be loosened, undercut and mixed after the previous harvest. The 10.6 inches sweeps in two overlapping rows undercut the soil profile along the entire machine width, creating a firm bottom. At the same time, soil is aggressively processed thanks to the working angle of the sweeps, creating a loosening top layer. Each sweep is mounted on a flexible tine that provides a 3D effect (horizontal and vertical movement) which protects the sweep from damage.

SB sweep section

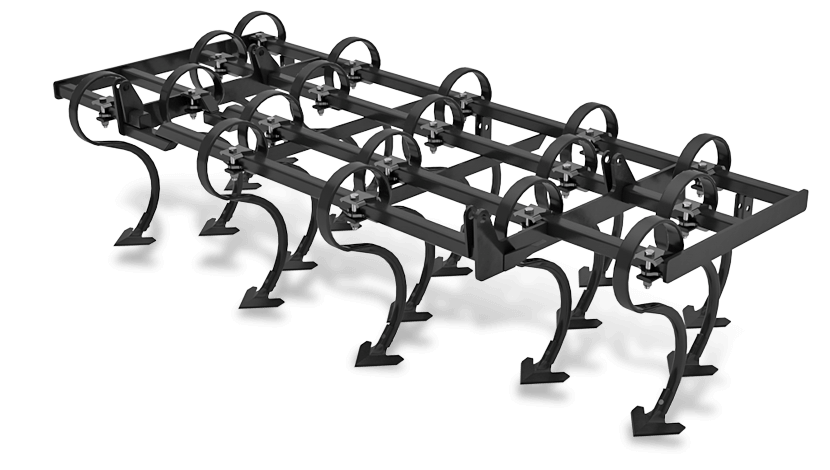

SB sweep section with spring sweeps (spring soil cultivation – sugar beet)

The section is especially suitable for spring cultivation before seeding sugar beet where it is required to adequately manage spring moisture, but still prepare a precise seedbed. The sweep angle does not mix soil vertically, but the soil is still undercut in the whole area thanks to the overlapping sweeps that are 6.7 inches wide. Another benefit is the reduced demand on the towing vehicle power.

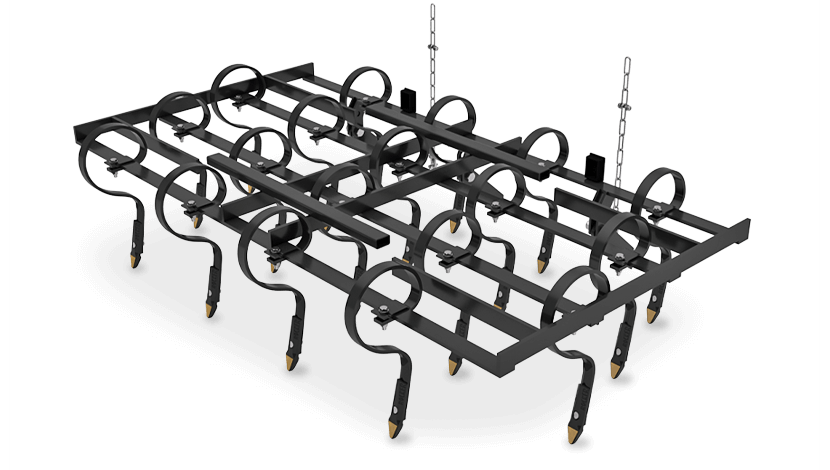

Gamma-point section

Gamma-point working section (spring soil cultivation – spring cereals, corn)

This section is suitable for early spring operations, such as required before seeding barley. The four rows of gamma points at a negative angle aerate and warm up soil without bringing wet particles to the surface, which preserves winter moisture. It is important for a fast start of growth of spring crop. The spring-loading of each tine enables working at high speed. The gamma points for this section are also available in the LONG LIFE version.

Maintains even cultivation depth along the entire machine width.

The Wave-Flex system means that the individual sections (width of 6.6 or 9.8 feet) are independently suspended on the side frames using the towing arms in the front and tracing arms in the rear. The system helps maintain the set working depth. The soil profile is evenly cultivated along the entire working width.

Do not lose time, work at headland without having to lift the machine.

The design of the SWIFTER SE cultivator enables turning the machine at headland without having to lift the working sections. Even so, we recommend turning on the headland with slightly excavated working sections and a larger turning radius. The telescopic connecting rods stabilize the side frames not only when turning, but also at higher working speed.

Smart folding for safe transport.

The SWIFTER SE wide cultivator can be easily folded into the transport position from the tractor cabin. The fully hydraulic folding of the working sections forward to the drawbar provides compact transport dimensions of up to 9.8 feet of transport width, required for transport on roads in EU countries.

Precise loosening of hardened soil.

The wide-span SWIFTER SE seedbed cultivators with a working width from 26 – 40 can be equipped with tractor track cultivators – either fixed, or telescopic. The SE 10000 and SE 12000 models can now be equipped with the transport axle track cultivators.

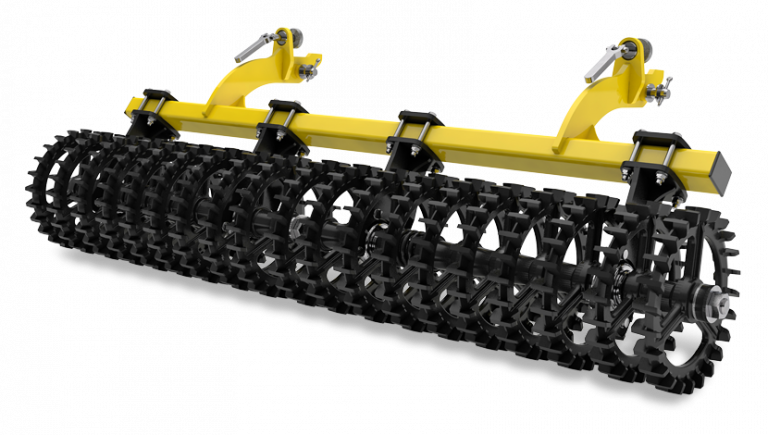

For maximum work quality.

The SWIFTER SE 10000 cultivator can be equipped with a third crosskill roller on request. The last crosskill roller has a diameter of 350 mm and creates the perfect soil structure, namely in difficult conditions, such as dry summer months.

TECHNICAL DATA

MACHINE DESCRIPTION

For interactive machine description go to https://www.bednar.com/ca/swifter-se/