Key properties

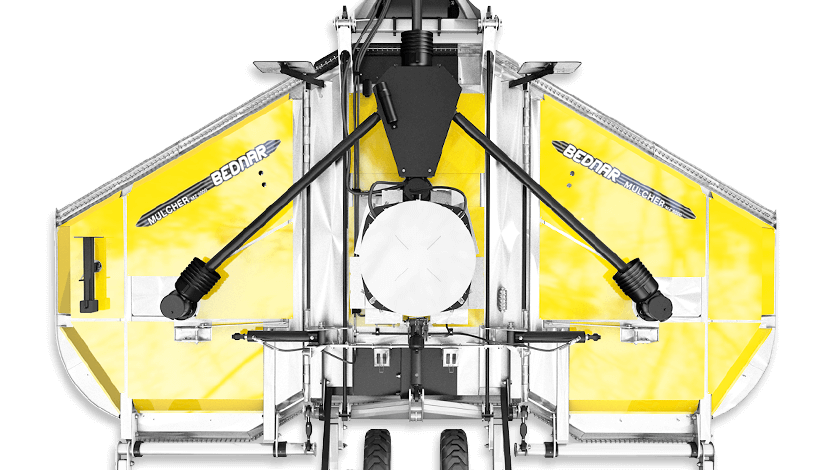

A wide rotary cutter with a robust design and a working width of 23 feet designed for large agricultural businesses, service providers, or for maintenance of large areas.

MULCHING

An essential operation in crop residue management.

- Mulching permanent grassland, pastures and meadows

- Mulching oilseed rape, cereal and corn stubble field

Mulching vegetation contributes to a balanced growth of above ground matter, processing ungrazed grass (bad quality fodder not grazed by the cattle), it promotes grass offsetting, and also prevents the development of weeds.

Ensures high durability and safety at work.

MULCHER MM wide rotary cutters are highly durable and designed for hard work. Hot-dipped galvanization of the machine provides high resistance to vegetation sap, collision with rocks or weather conditions.

Perfect material cutting and disrupting in one pass.

Quality mulching requires a large rotor diameter and high circumferential speed. The MULCHER MM wide rotary cutter is equipped with two pairs of shaped knives on the rotor to ensure excellent quality of work. The blades can be used both for mulching grasses and processing crop residue.

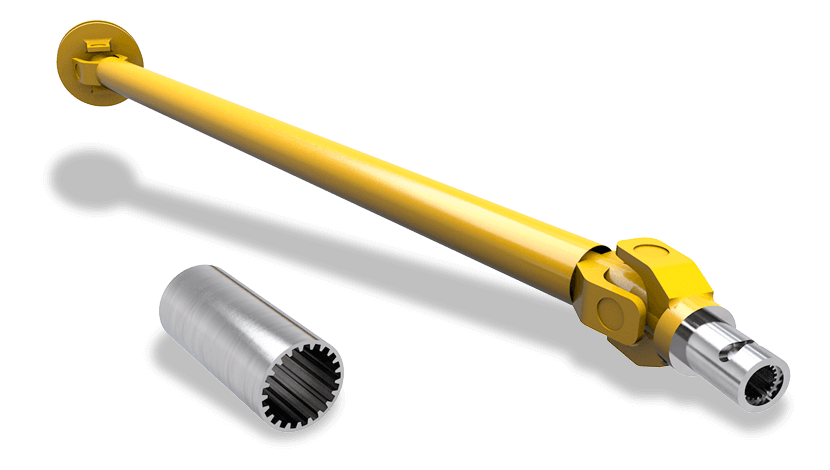

By Walterscheid.

When manufacturing BEDNAR rotary cutters, we use high-quality cardan shafts by Walterscheid.

For better terrain tracing.

When compared with the standard model,The MULCHER MM can be equipped with a stepping version of the central axle. The machine is then able to better trace any terrain unevenness and maintain the set working width. You can achieve an even better effect in combination with the tandem version of the side axles.

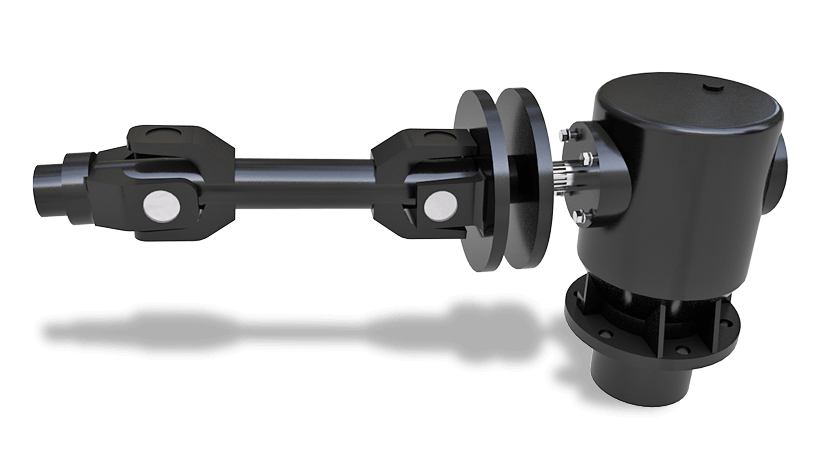

An effective protection of the gearbox.

The transmission part of the MULCHER MM wide rotary cutter is protected against damage (for example, in the case of a collision with a rock, etc.) with a friction clutch that automatically stops all the transmission processes. The cardan shaft connecting the tractor with the gearbox is equipped with a friction clutch.

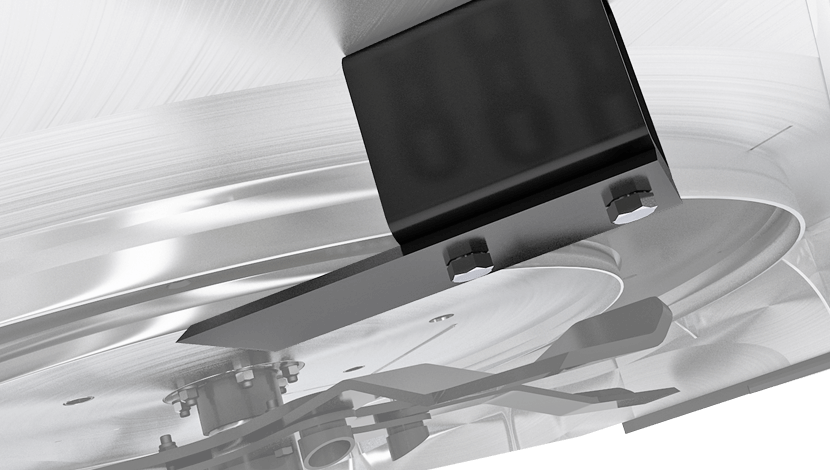

Prevents dirt from sticking to the machine.

MULCHER MM can be equipped with cover plates of the main frames. The plates are smooth and minimize the sticking of plant residue on the machine.

Machine cleaning equipment.

The main component is the fan that creates a stream of air and the wind straighteners direct air to the risk areas on the machine surface. The equipment prevents dirt and plant matter from sticking on the machine surface. It improves labour safety and reduces time spent with cleaning.

Front counter blades, spreading deflector or armouring.

- FRONT COUNTER BLADES

- SPREADING DEFLECTORS

- ARMOURING

Counter blades that provide the final cutting of the mulched material are installed in the front part of the mulching area to increase the chopping effect that easily increases the quality of material mulching.