KEY PROPERTIES

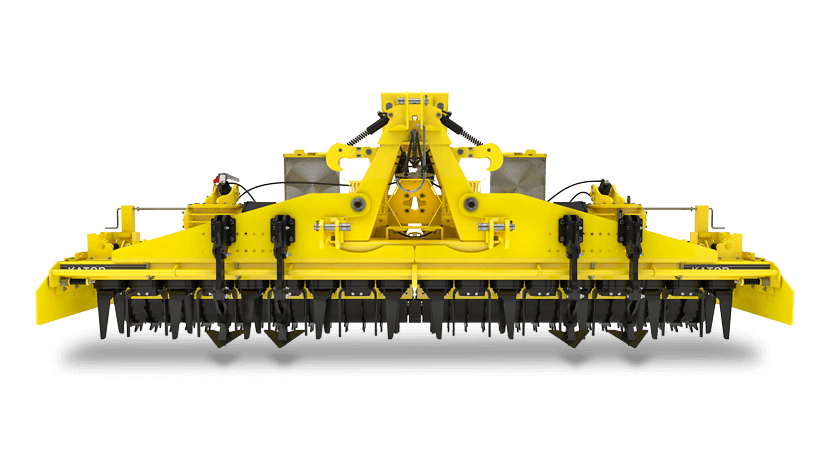

A rotary harrow for even soil profile cultivation and quality seedbed preparation, especially in heavy, hard and dry soils.

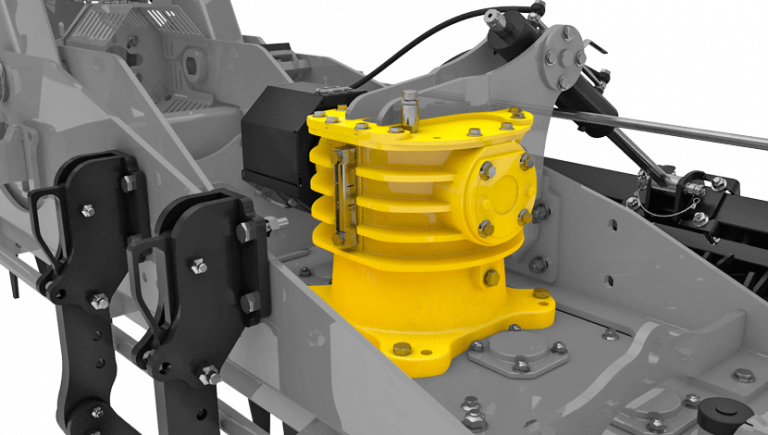

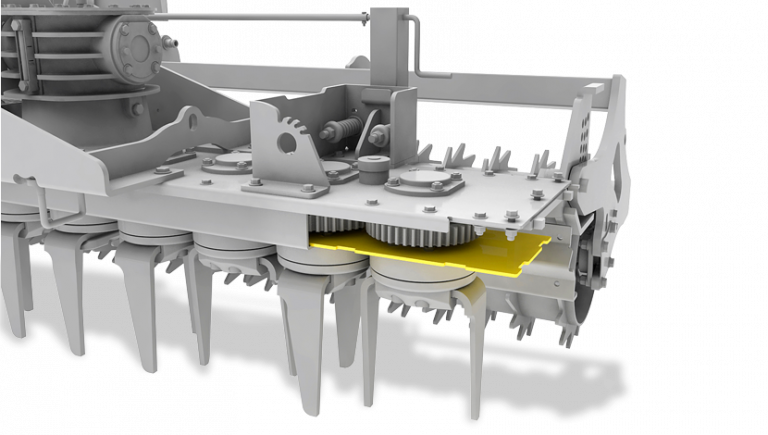

For perfect power transmission.

The central shaft is the main part of the rotary harrow and the most used component. The connection between the special solid crown with an elongated case and a reduced central shaft (2.95 inches) provides for a perfect transfer of force between the gearbox and the cascade of gearwheels.

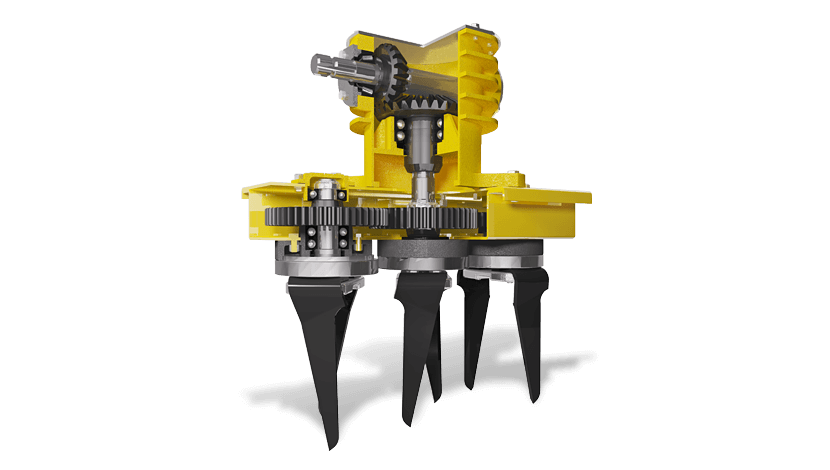

A design that no-one else offers.

Each rotor is equipped with three bearings (the shaft is mostly surrounded by bearings). This system provides for perfect rotor stability and protects gearwheels, shafts and gaskets from damage. No other competitor offers three bearings per rotor.

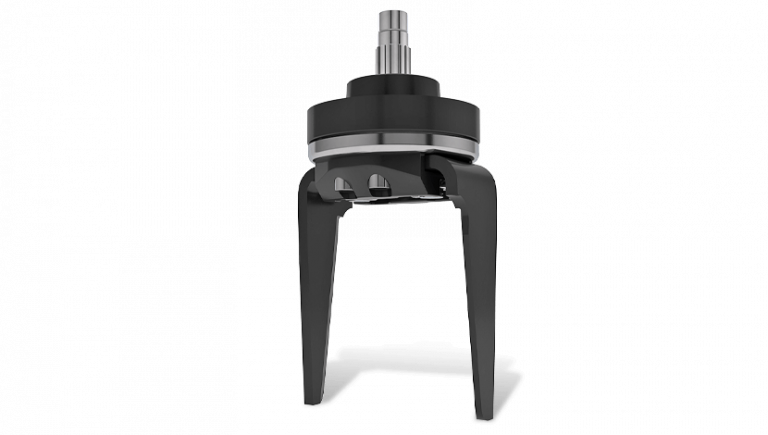

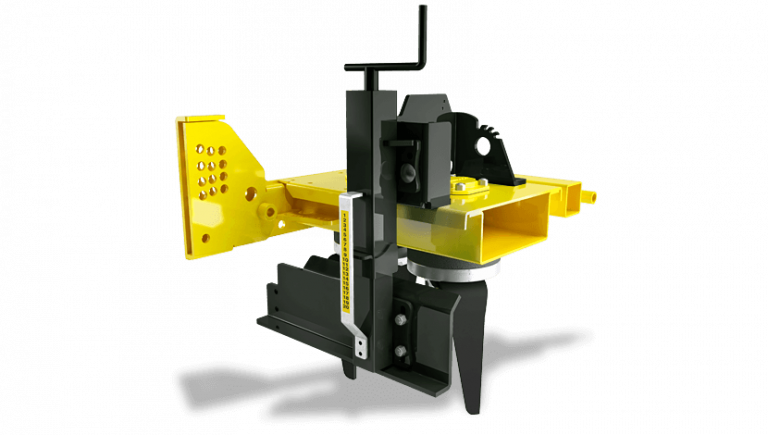

Easy replacement without the need for special tools.

A quick and easy blade replacement. Just pull out the cotter, remove the pin and replace the blade. It is a system designed to be used without any special tools and equipment.

Avoid rotor damage.

The special “STONE” equipment prevents stones from penetrating or sticking between the blade holder flange and the rotor. The bearing holder and cover are made from one part. The cover is screwed to the machine frame and the shaft turns inside the cover. This way, no foreign objects that could damage the gasket or bearing can enter the rotor area.

Perfectly cultivated soil.

The folding arrangement of the BEDNAR KATOR rotary harrow offers only (9 inches) between rotors. A larger number of rotors per metre of the working width improves soil crumbling.

Prevents clogging and creating waves.

The rear levelling bar is very close to the rotors. This design is better for higher quality of soil levelling (a greater distance between the rotor and the rear levelling bar creates waves).

Stronger than in any other competing machine.

The bottom part of the main frame of the gearbox cascade of gearwheels is made of steel with a thickness of 0.5 inches. The main gearbox is not filled with oil but with a highly viscose grease that ensures reliable lubrication of the gearwheels. Also, the risk of oil leak into soil is eliminated in case of tub damage, such as puncture.

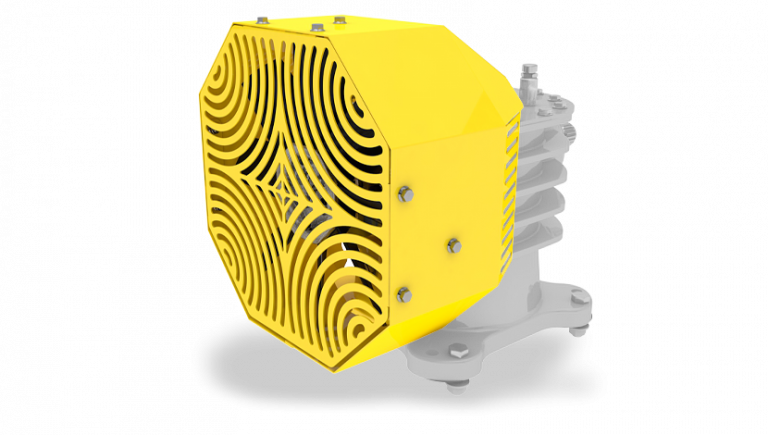

A quiet operation, a long-lasting engagement.

The KATOR KN 6000 model and the KN_PROFI model series can be equipped with external gearbox oil cooling for intense long-lasting operation without overheating.

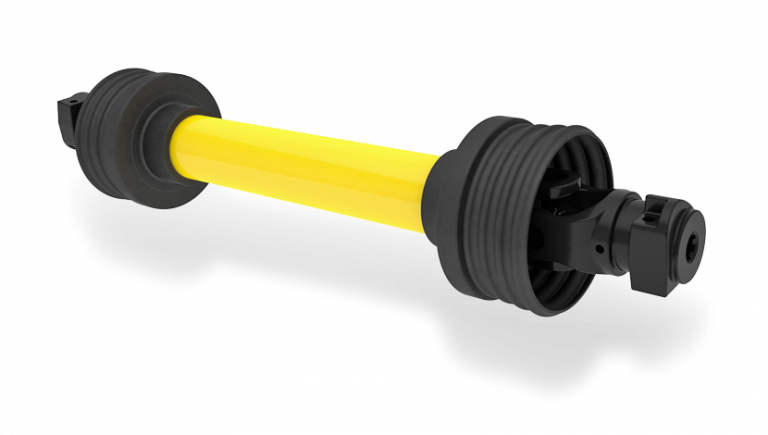

By Walterscheid.

The KATOR KN rotary harrows have high quality cardan shafts by Walterscheid in various dimensions according to the model.

TECHNICAL DATA

MACHINE DESCRIPTION

For interactive machine description go to https://www.bednar.com/ca/kator-kn/